Company Location

Auto Nagar, E-Block, Plot No - 64,

Gajuwaka, Visakhapatnam

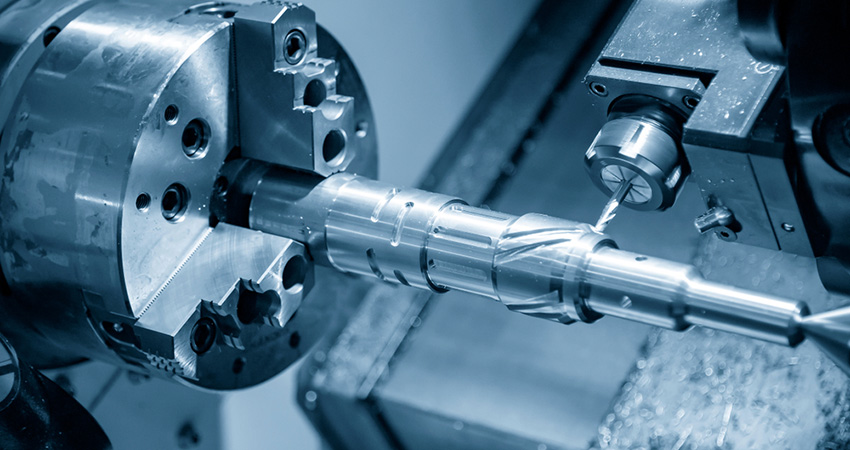

CNC turning, also known as computer numerical control turning or CNC lathing, is a machining process used to create cylindrical parts by rotating a workpiece while a cutting tool removes material to form the desired shape. CNC turning is commonly used to produce components such as shafts, rods, and sleeves with precise dimensions and surface finishes.

Experience unmatched precision and reliability with Sri Renuka Yellamma Engineering Pvt. Ltd's CNC turning services. We specialize in providing high-quality machining solutions tailored to meet the diverse needs of our clients across various industries. With state-of-the-art equipment, advanced technologies, and a team of experienced professionals, we deliver precision-engineered components that exceed expectations.

CNC lathes can achieve extremely tight tolerances and high levels of accuracy, ensuring consistent part quality.

Automated operation reduces the need for manual intervention, leading to faster production times and increased productivity.

CNC lathes can produce a wide range of cylindrical parts with varying diameters, lengths, and features.

Once programmed, CNC lathes can produce identical parts with minimal variation, making them ideal for high-volume manufacturing.

Design: The process begins with the creation of a digital design or CAD (computer-aided design) model of the part to be manufactured.

Programming: The CAD model is translated into instructions for the CNC lathe using CAM (computer-aided manufacturing) software. These instructions specify the toolpaths, cutting parameters, and other machining parameters needed to produce the part.

Setup: The workpiece is securely mounted in the chuck of the CNC lathe, which rotates the workpiece at high speeds. The cutting tool, typically a single-point cutting tool or a carbide insert tool, is mounted on a tool turret or tool post and positioned in proximity to the rotating workpiece.

Execution: The CNC lathe executes the programmed instructions, moving the cutting tool along the surface of the rotating workpiece to remove material and form the desired shape. The cutting tool may move along multiple axes to achieve complex geometries, such as contours, fillets, and threads.

Finishing: After the rough machining is complete, additional operations such as facing, grooving, drilling, and threading may be performed to achieve the final part dimensions and surface finish.